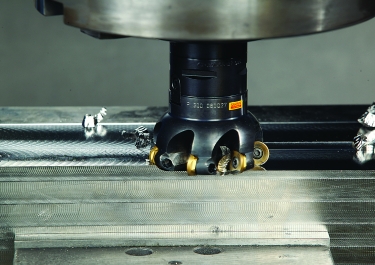

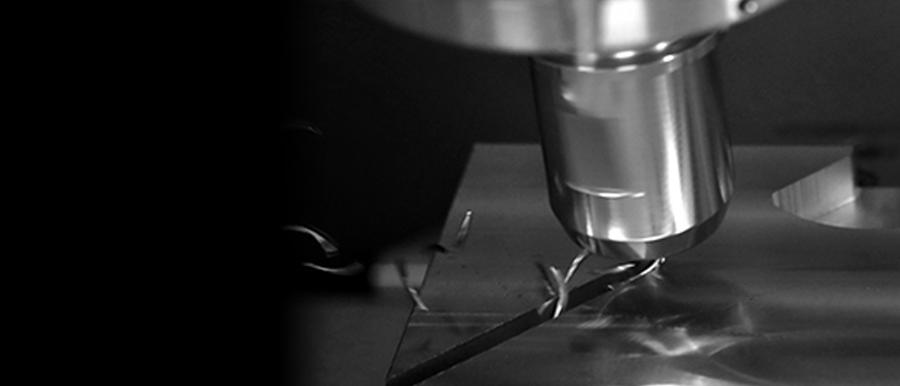

Cutting tool and workpiece engagement during 5-axis milling operations. | Download Scientific Diagram

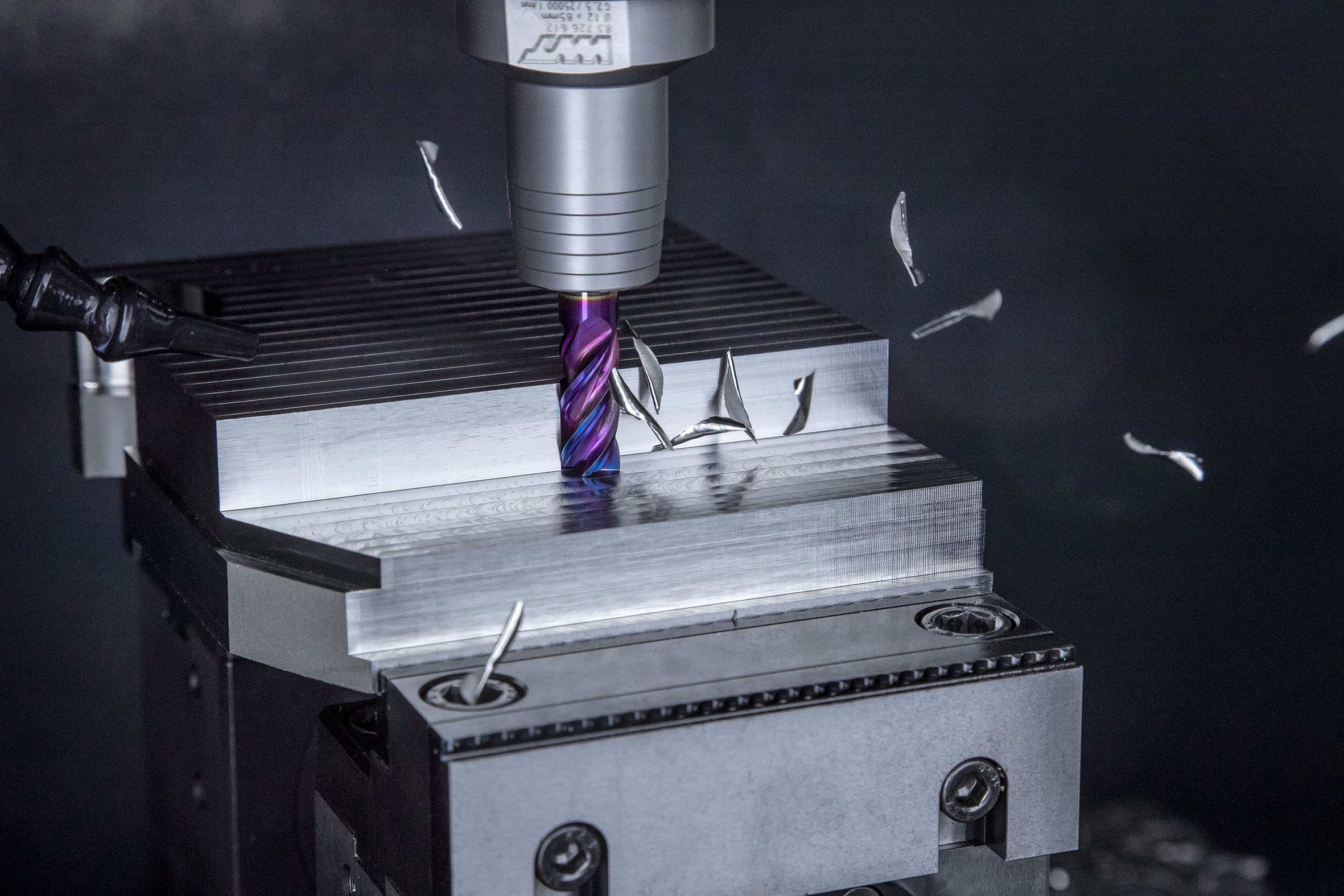

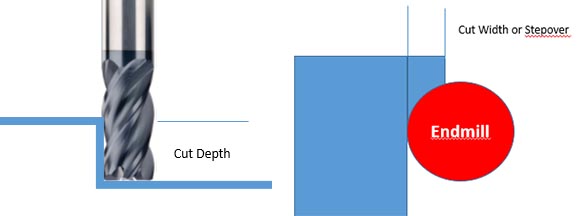

Applied Sciences | Free Full-Text | Analysis and Prediction of the Machining Force Depending on the Parameters of Trochoidal Milling of Hardened Steel

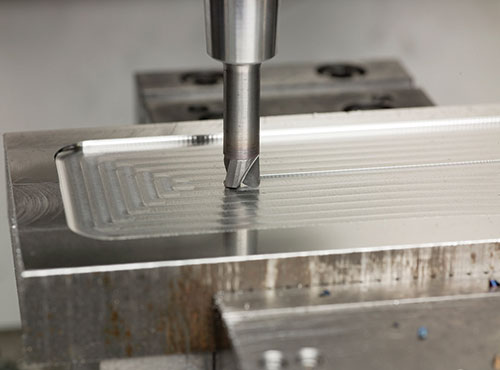

FEM Analysis to Optimally Design End Mill cutters for Milling of Ti-6Al-4V-end mill- WOTEK Precision Tools Co., LTD. -WOTEK Precision Tools Co., LTD.

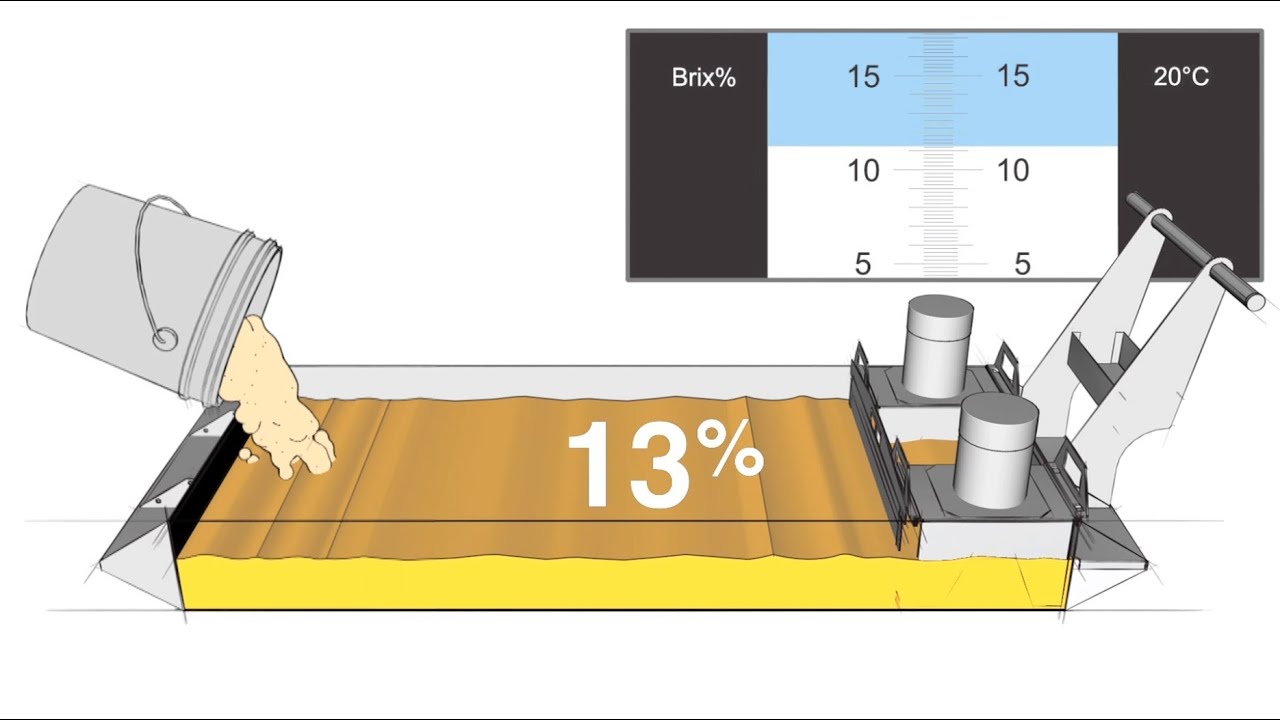

On modelling coolant penetration into the microchannels at the tool-workpiece interface - ScienceDirect

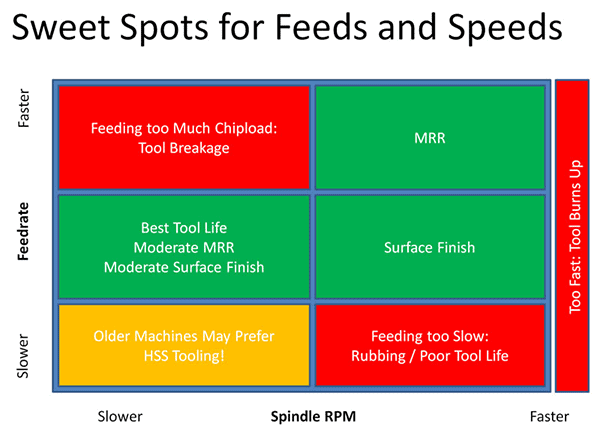

![High Speed Machining (HSM) [ Definitive Guide ] High Speed Machining (HSM) [ Definitive Guide ]](https://www.cnccookbook.com/wp-content/uploads/2017/08/SurfaceSpeedVsHeatHSM.jpg)